LOAD CAPACITY CALCULATIONS & DESIGN EVALUATIONS

THE INTERNATIONAL STANDARDS PROVIDE DIFFERENT SYSTEM OF PROCEDURES FOR THE CALCULATION OF THE LOAD CAPACITY OF MECHANICAL COMPONENTS.

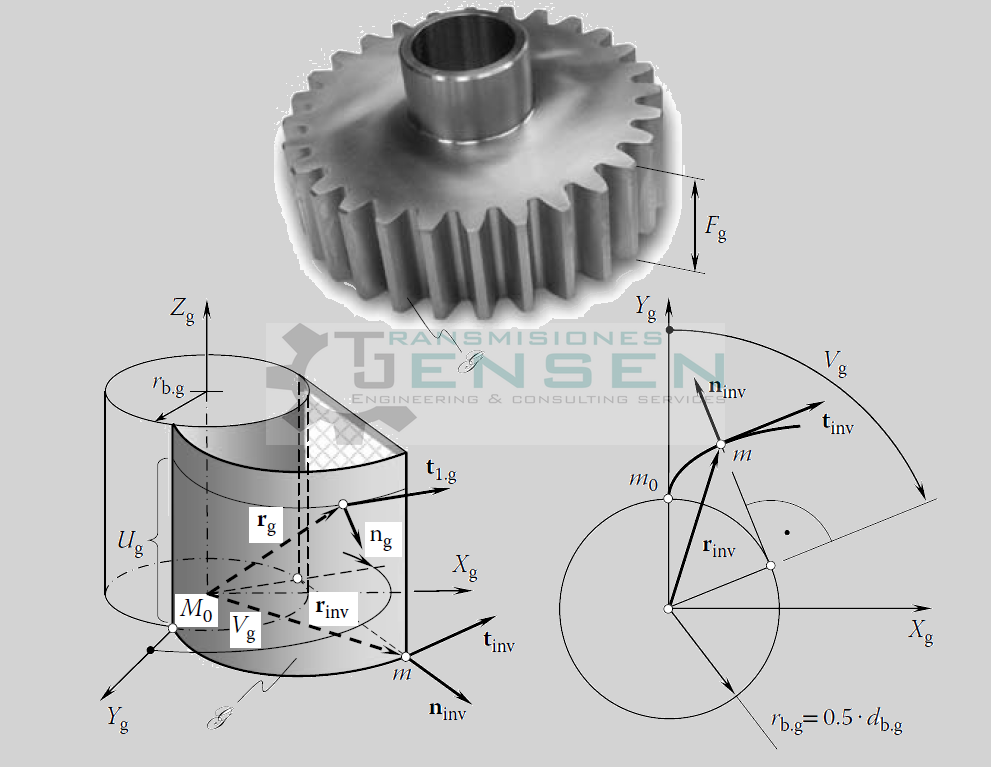

- a) Gears

Description:

The calculations of the load capacity of involute and non-involute gears profile, such as Novikov and cycloid gear profile are based on pitting, micropitting, tooth root breakage, scuffing and wear rating factors. Rating calculation provides a method by which different gear designs can be compared by the experienced gear designers.

Objetives:

To develop gear designs evaluation according to different rating method.

To establish a common base for rating various types of gears - b) Shafts & Axles

Description:

The most common causes for damages to shafts and axles are endurance failures. A deeply calculation of safety against the fatigue failures and damages due to maximum load are always necessary.

Objetives:

To develop shafts and axles verification by determining the safety factors from endurance failures and damages due to maximum load. - c) Rolling bearings & Plain journal bearings

Description:

Many international standards describe specific methods of calculating the basic dynamic load rating of rolling bearings and the hydrostatic and hydrodynamic calculations of plain journal bearings, in accordance with good manufacturing practice and of conventional design.

Objetives:

To evaluate rolling bearings rating and to develop hydrostatic and hydrodynamic calculations of plain journal bearings. - d) Flexible and rigid coupling

Description:

The basic function of a coupling is to transmit torque from the driver to the driven machine. Particularly flexible couplings expand upon the basic function by also accommodating misalignment and end movement.

Objetives:

To apply different procedures to compare couplings and/or determine its torque rating.